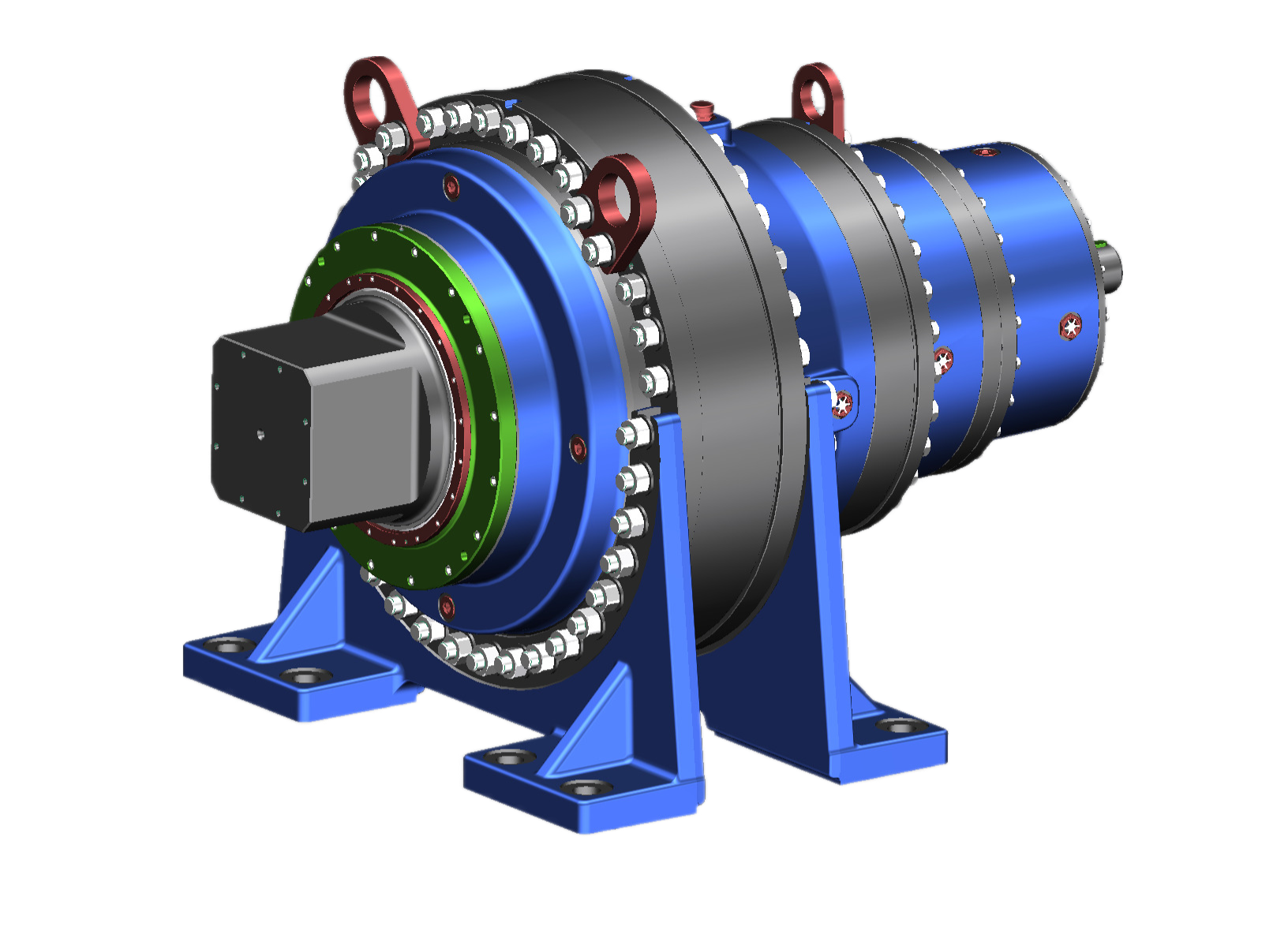

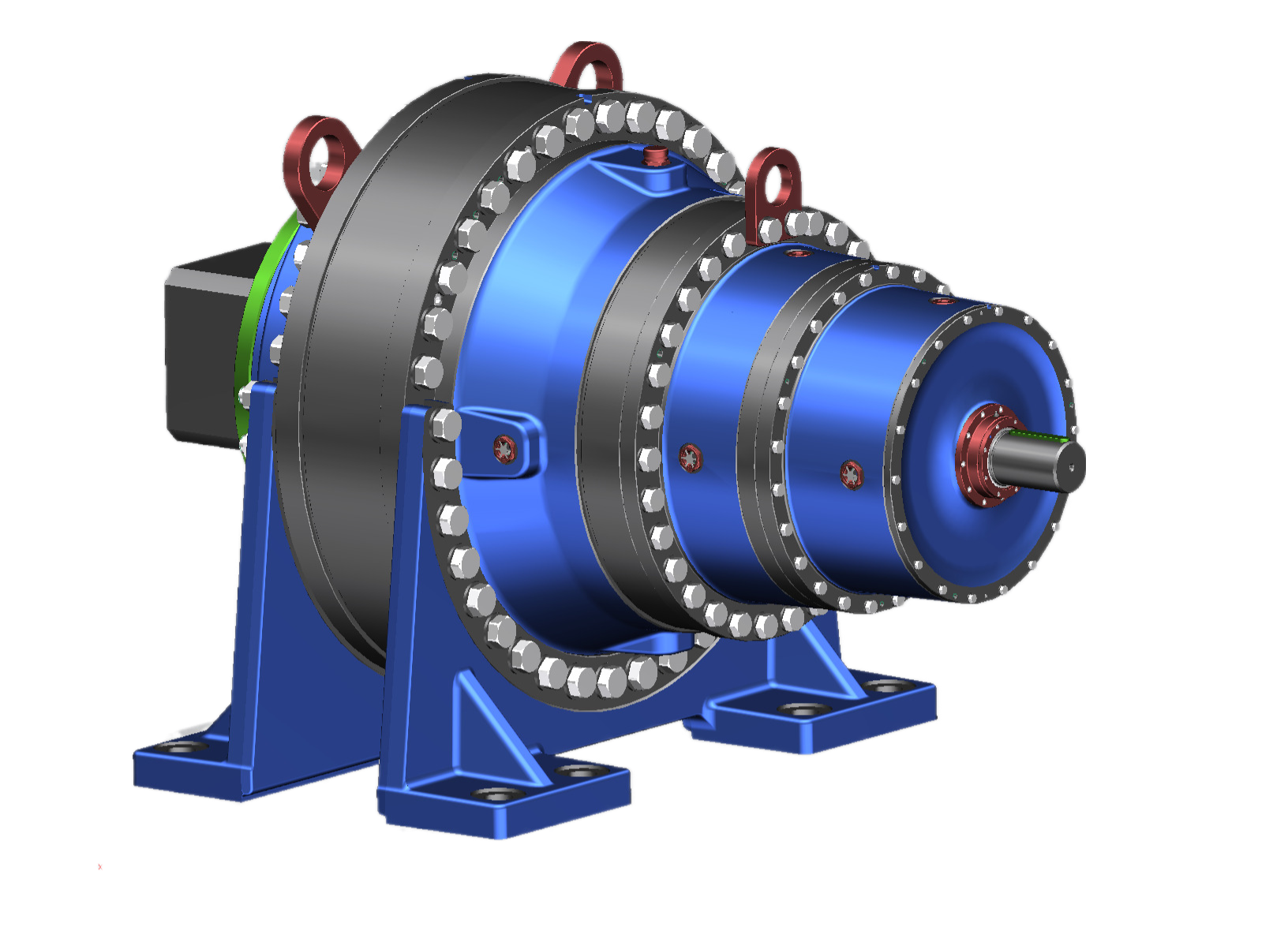

The gearboxes are specialized and engineered specifically for sugar industry applications, including the Cane Mill, GRPF (Greenfield Research & Plantation Facility), and various Carrier applications. This indicates a tailored design to meet the specific operational needs of sugar production machinery.

Learn MoreThe components such as gears, shafts, ring gears, satellite carriers, and pins are manufactured according to European quality standards. This suggests a commitment to high-quality manufacturing processes and adherence to stringent European standards, which are often associated with reliability and superior performance.

Learn MoreThe bearings used in the planetary gearbox are selected to achieve a minimum life of 100,000 hours, emphasizing longevity and durability. This long service life is crucial for the sugar industry, where machinery is expected to perform reliably over long periods.

The statement mentions strict adherence to ISO DP 6336 and ISO 281 norms to ensure the precision and quality of the planetary gearbox. The use of Timken or Schaeffler brand bearings, which are well-known for their quality, further underscores the commitment to high standards in the gearbox's construction.

Learn More